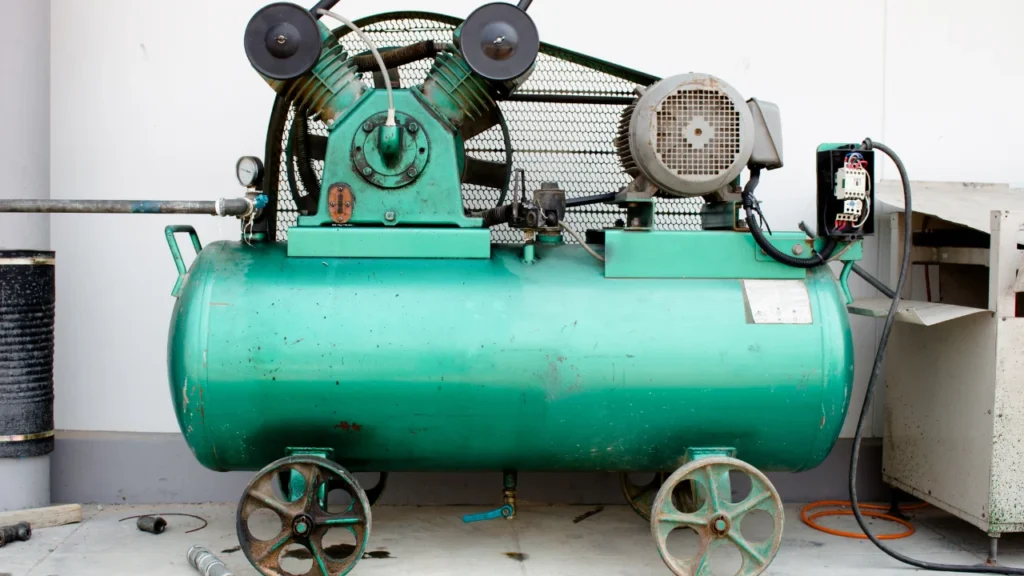

An air compressor is an essential tool for many households and workshops. Proper maintenance keeps your compressor working efficiently for years to come. Cleaning your air compressor regularly removes moisture, debris, and dirt that can damage components. In this article, we will guide you on how to clean an air compressor properly.

9 Easy Steps To Clean An Air Compressor

Follow these steps to clean your air compressor properly.

Get The Right Tools

To make the cleaning process easier, you should have the right tools on hand. The tools include wrenches, screwdrivers, pliers, cleaning rags, oil, lubricant, and replacement air filters. Having these tools readily available will save you time and effort during the cleaning process.

Drain Water From Tank

It’s important to regularly drain water that stores in the air compressor’s tank. Water can condense inside the tank and needs to be drained to prevent corrosion. So, locate the drain valve at the bottom of the tank. Place a container under the drain valve to catch the water. Slowly open the drain valve and allow all the stored water to fully drain out. Once it seems all the water has drained then close the drain valve. Dispose of the drained water appropriately.

Wipe Down Exterior

Use a clean rag and a mild cleaning solution to thoroughly wipe down the outside of the air compressor’s tank and motor. Pay close attention to any dirt, grease, or oil build-up, especially around the output fittings and connections. These high friction areas tend to accumulate more grime over time. Be sure to fully dry all surfaces once wiping is complete.

Clean Air Filter

Cleaning the air filter is a crucial and relatively simple task that can drastically improve the performance of your air compressor. To start cleaning air filter, first turn off and unplug the air compressor. Now, carefully remove the air filter, making sure not to damage it. Take it outside and use compressed air to blow out the dust and particulates.

If the filter is too dirty or damaged, it’s best to replace it. Once cleaned or replaced, reinstall the air filter securely before turning the compressor back on.

Inspect Belts

The drive belts of your air compressor are another critical component to inspect and maintain. Signs of wear and damage, such as cracking or glazing, can lead to belt failures and costly compressor damage.

To inspect the belts, first locate them. Run your fingers along the belts carefully to identify any not-so-visible damages. If you spot any signs of wear, replace them promptly with new ones of the appropriate type and size. After installing new belts, check the belt tension. It should be tight enough to prevent slipping but not so much that it strains the compressor components.

Clean Air Intake

Cleaning the air intake is essential to ensure good airflow, as this is where the compressor draws in outside air. Dust and debris can accumulate here over time, which could potentially enter the compressor.

To clean the air intake, locate the intake opening, typically found on the back or side of the compressor. Use a vacuum cleaner with a brush attachment to remove any loose debris.

After vacuuming, use a small brush to dislodge any additional debris stuck to the intake grille or screen. Vacuum again to pick up any remaining particles. Lastly, wipe down the inside of the air intake chamber with a dry cloth and ensure the intake opening is clear and unobstructed.

Check Safety Valve

Safety valve helps to prevents damage from excess pressure buildup in the air tank, so its very important to inspect the safety valve. To check the safety valve, identify its location on the air tank – it’s usually topped with a lever or a knob. Engage the safety valve briefly by pulling up on the lever or turning the knob. If the valve is functioning properly, you should hear a release of air pressure. If air continues to leak, it signifies that the valve is stuck open and needs repair or replacement.

Replace Oil

Regular oil replacement is key to the smooth and efficient operation of your air compressor. Here are some steps to guide you through the process:

Drain Old Compressor Oil: Locate the oil drain plug, typically at the bottom of the compressor tank or crankcase. Remove the plug and allow the old oil to drain out completely into a container placed underneath.

Refill With New Oil: Refill the compressor with the oil type and amount recommended by your owner’s manual. Avoid overfilling. Replace the plugs when finished.

Dispose Of Old Oil Properly: The old oil will likely contain contaminants and metal shavings. Check local hazardous waste disposal procedures to properly dispose of the used compressor oil.

Inspect Hoses

Regular inspection of air hoses for wear, cracks, and leaks is necessary. Over time, the outer rubber casing can become brittle and crack, while the inner hose can develop pinhole leaks. Any damage or leaks found should be addressed immediately to avoid a dangerous blowout. So, keep spare hoses of the appropriate size and rating for your compressor on hand and consider replacing standard hoses every few years as a preventive measure.

Air Compressor Maintenance Checklist

Maintaining your air compressor means conducting daily, weekly, monthly, and yearly checks. Regular checks help identify potential issues before they escalate, ensuring your machine’s longevity.

Daily Checks

Before using your air compressor, conduct a visual inspection. Look out for any oil leaks that might affect the machine’s operation. If the oil level is low, be sure to top it up. Remember, running an air compressor with low oil can cause extensive damage. You also need to drain the tank to get rid of any collected moisture. Inspecting the belts and testing for air leaks should be part of your daily routine.

Weekly Checks

After a week of usage, it’s time to revisit the oil levels. Make sure the oil is up to the recommended scale. Pay extra attention to the air filter; a clogged filter can affect your air compressor’s performance. If it’s in bad shape, replace it immediately.

Monthly Checks

A month’s usage means your compressor has clocked significant operational hours. This period calls for an in-depth inspection. Start by checking for leaks, then inspect the safety valves. Belts should be in good working condition, and all bolts must be tightly secured.

Yearly Checks

Yearly checks are essentially a comprehensive inspection of your air compressor. This includes checking all parts, servicing the pump and engine, and running multiple operational tests.

Conclusion

Cleaning your air compressor is not a difficult task if you know the right steps. Regular cleaning not only keeps your air compressor in good shape but also prolongs its lifespan. By following this comprehensive guide, you can ensure that your air compressor stays in excellent condition for years to come. Remember, a well-maintained air compressor is an efficient and reliable one.

Read Also: